I

came across an interesting and informative technical piece

on the website of Mark Williams Enterprises (www.markwilliams.com)

that discusses driveshafts. I thought it was good information

so I'm sharing here with you.

Operating

Angle

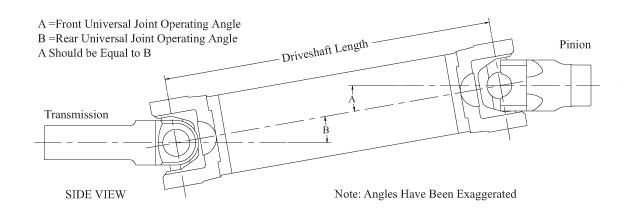

Operating angles in a driveshaft are the angles between

the pinion, driveshaft and transmission centerlines. The

optimal angle for any driveshaft to run at is 0 degrees,

where many vibrational and frictional problems are non-existent.

In order to minimize power loss and vibration in an offset

configuration, the pinion centerline and the transmission

centerline need to be parallel. In general, the largest

angle for racing applications should 2 degrees and the centerlines

should be parallel within 1/2 degree. With suspension movement

the operating angle will increase, but should not exceed

15 degrees. If the centerlines are off too far, the u-joints

travel at uneven operating velocities, causing vibration

(this is the same problem induced by poorly phased end yokes).

This vibration is hard to distinguish from an unbalanced

driveshaft.

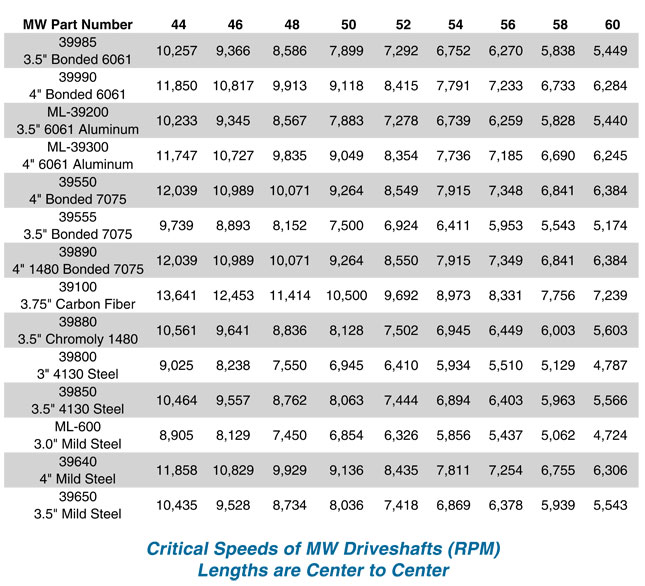

Critical

Speed

Critical speed is the speed at which a spinning shaft will

become unstable. This is one of the single largest factors

in driveshaft selection. When the whirling frequency and

the natural frequency coincide, any vibrations will be multiplied.

So much that the shaft may self destruct. Another way to

think of this is that if a shaft naturally vibrates at 130

times a second, and one point on the shaft passes through

0 degrees 130 times a second (7800 RPM) then the shaft has

hit a critical speed. There are several ways to raise the

critical speed of a driveshaft. You can make it lighter,

stiffer, or increase diameter without increasing weight.

This is the reason carbon fiber makes a good driveshaft,

it is stiff and light and can be made to any diameter or

wall thickness. Aluminum, while it has a very good critical

speed is not quite as strong as steel. Steel, with good

strength characteristics will have a lower critical speed.

|