(More

tech articles on the Tech, Tests & Installs page

HERE) (More

tech articles on the Tech, Tests & Installs page

HERE)

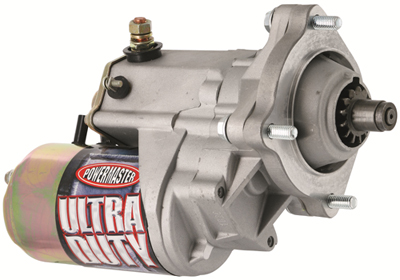

Publisher's

note: I was on the website of our friends at Powermaster

Performance, makers of racing alternators and

starters, and saw this very informative article that

I thought would be helpful to share with you here.

CHOOSING

A STARTER CHOOSING

A STARTER

1)

Torque Requirements

The torque output of a starter is the most important

consideration. The starter must be able to spin the

engine, and do it without overheating internally. Since

there is no such thing as having too much torque -even

on a street vehicle - a 200 ft.lb. starter will work

for everyone. Speaking in general terms, a over 12:1

compression or higher engine should use a 200 ft.lb.

starter. Engines up to 12:1 should use at least a 180

ft.lb. starter. 160 ft.lb. starters are good for engines

up to 10.5:1.

One

thing to keep in mind is that the torque characteristics

of a starter are a function of its design. High voltage

batteries or low internal resistance batteries will

affect the kilowatt output of the starter by changing

the output speed but not the torque. Therefore, buy

enough torque to begin with.

2) Fit

Of course for a starter to work, it must fit the application.

Consider headers, oil pans, and the mounting points

on the engine. What size ring gear do you have (for

Chevy applications)? Does your Chevy block accommodate

a straight mount starter, or is the only pattern drilled

in the engine block for a diagonal or offset pattern

starter? In racing, did the oil pan manufacturer lock

you into a particular shape of starter? In your Ford

application, is your ring gear 3/8” from the engine

plate - indicating a typical manual transmission starter

- or is it closer to a 3/4” - requiring a typical

auto transmission unit? How tight are the headers around

the starter? These are just some of the questions that

will help you determine the right starter for your application.

3)

Weight

Lastly,

depending on the form of racing, the overall weight

of the starter is a consideration.

TORQUE

DEFINED:

Torque

is the ability to overcome rotational resistance. High

compression, large displacements, tight rings, blowers,

and other factors all offer rotational resistance -

and it takes torque to overcome this. Unfortunately,

starters are rated in kilowatts. This is a measure of

its torque and speed combined. The torque output is

really unknown.

Starters,

like engines, have different powerbands. Some have a

maximum power point at a relatively high RPM with little

torque. Whereas others produce more torque and yet lower

RPM. In the performance environment, torque is the most

important consideration, generally because a performance

engine offers more rotational resistance than stock.

As a result, kilowatt ratings can be confusing because

two starters with the same kilowatt rating can have

very different torque characteristics.

The

engine will demand a certain amount of torque for cranking.

When the torque demands cause a starter to exceed its

maximum power point, the extra input energy is wasted

as internal heat. Asking a starter to produce more torque

than it is comfortable with results in low electrical

to mechanical efficiency and drastically increased internal

heat. This is what causes premature starter failure.

The key is to use a starter that has a power peak at

a high torque point. Then, in the event that the cranking

conditions offers high resistance, the starter will

have the torque characteristics to handle it without

overheating. The

engine will demand a certain amount of torque for cranking.

When the torque demands cause a starter to exceed its

maximum power point, the extra input energy is wasted

as internal heat. Asking a starter to produce more torque

than it is comfortable with results in low electrical

to mechanical efficiency and drastically increased internal

heat. This is what causes premature starter failure.

The key is to use a starter that has a power peak at

a high torque point. Then, in the event that the cranking

conditions offers high resistance, the starter will

have the torque characteristics to handle it without

overheating.

Several

other factors effect starter performance dramatically.

Voltage is very important. Cabling and quality disconnect

switches are important because under heavy load, voltage

will be lost or "dropped" in undersized or

hot cables, or hot switches. The internal resistance

of the battery itself results in decreased voltage to

the starter. Therefore, low internal resistance batteries

like typical 1000CCA - or better yet - spiral cell AGM

batteries such as Optima and others should be used.

High voltage batteries like the new 16 Volt Powermaster

battery is a perfect choice for any racing application.

When

you purchase a Powermaster starter you will get a dyno

sheet that shows you the exact performance of your starter.

The sheet itself will explain how to interpret the data,

but you can be assured that Powermaster starters are

built to a consistent, statistically controlled standards,

and that they are dynamically tested throughout their

entire power range.

|

|

Source:

Powermaster Performance

www.PowermasterPerformance.com |

Dragtime

News On Location |

Tech,

Tests & Installs |

Bracket

Racing 101 |

|

|

Visit

the Tech,

Tests & Installs main page. |

Visit

the Bracket

Racing 101 main page.

|

|

|

|

|

|

|